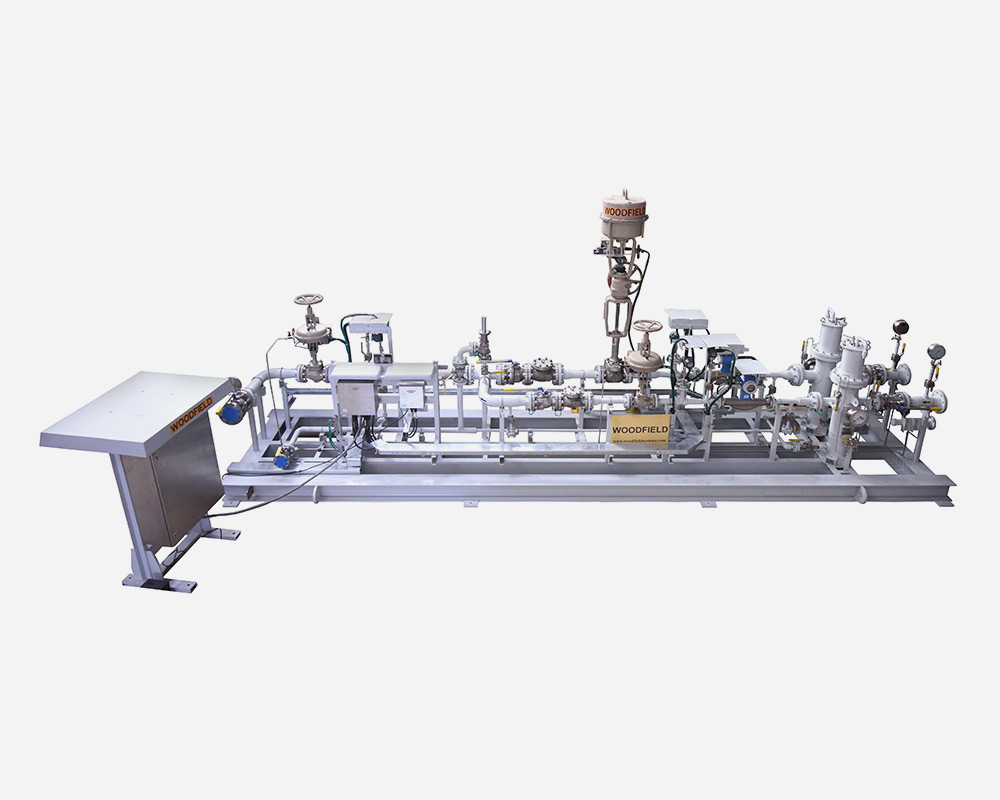

Chemical dosing skids are used to inject chemicals in the process where injection in specific quantities is necessary.

Woodfield’s chemical dosing skids solutions are used to dose the preset quantity of chemical into the process pipeline as per desired proportion.

These chemical injection skids have low flow rates and skid is kept near the injection point. Chemical storage tanks are mounted on the skid to store the chemical to be dosed. PD pump as per API 675 to feed the chemical into the process line.

The capacity of the pump can be varied with stroke adjustment either manually or automatically.

A control panel is provided to operate the pump locally. These chemical dosing skids are available with capacities ranging from 2 LPH to 2000 LPH for dosing.

Skid size and rating: 1/2’’ to 2’’ 150 # / 300# / 600#.

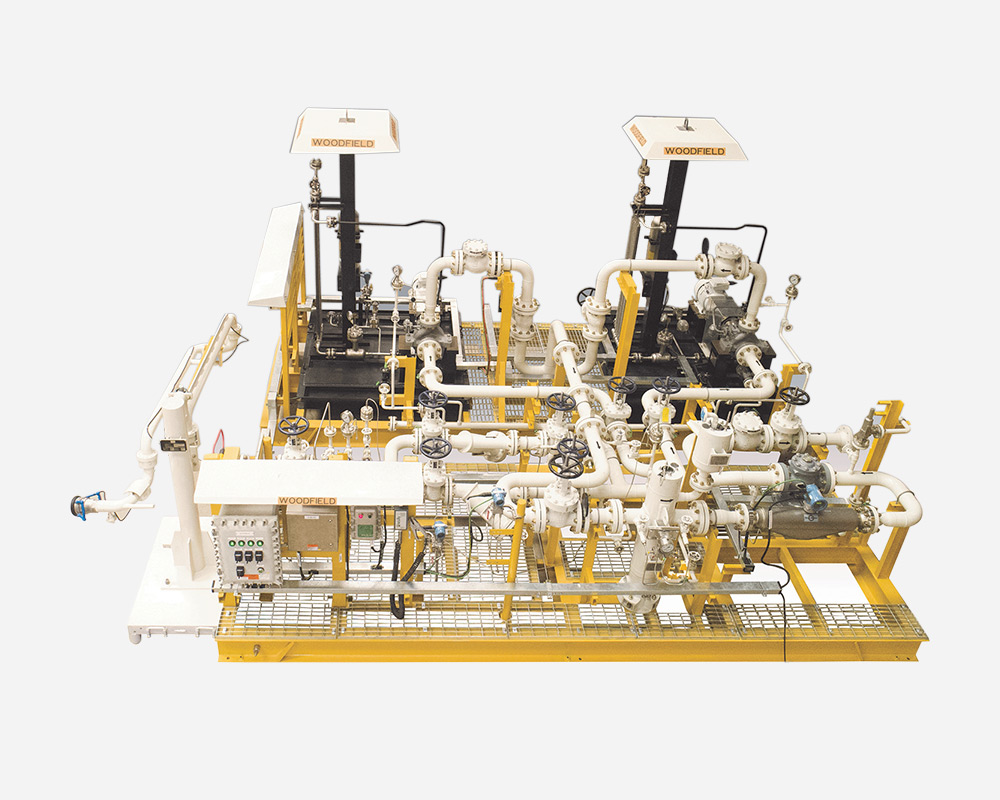

Features

- Skid is designed with pump protection device and associated interlocks.

- In-house manufacturing (i.e. fabrication, assembly, system integration and testing facility) on a single frame makes it plug and play device and ensures minimum site work.

- Pump calibration local or remote (using DCS) is possible.

- In-tank mixing facility is available with motor driven agitator.

- Manaul or automatic stroke adjustment.