Woodfield Emergency Release Couplings (ERCs) have been the most reliable couplers across the globe for quite some time now, ensuring safety of the operators and the environment in case of emergency.

Woodfield couplers are designed & manufactured keeping in mind all the safety parameters required during transfer of products from terminal to tanker or vice-versa. These ERCs can be used with hoses or loading arms.

In case of an emergency if the tank truck moves during loading, ERC gets activated and detaches from the hose or loading arms safely with minimum spillage by instantly closing the safety valves in the ERC.

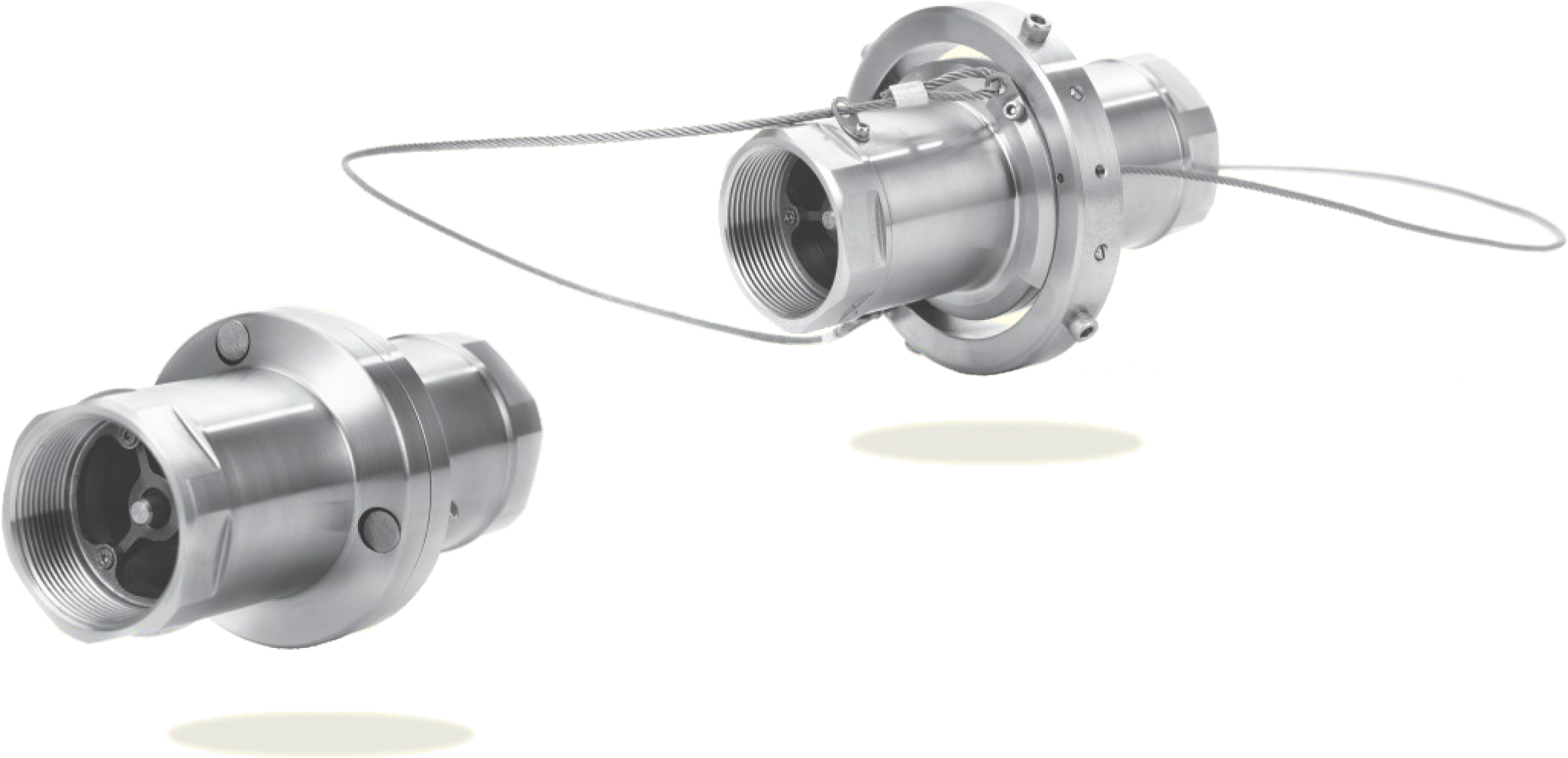

Woodfield has designed two types of ERCs for different needs – Shear Pin (S-ERC) Type & Cable Release (C-ERC) Type.

Features of S-ERC and C-ERC

- Safe & reliable

- Spill-free separation

- High flow rate / low pressure drop

- Simple design & easy to maintain onsite

- Coupling automatically senses an excessive load and closes the valves and disconnects

Shear Pin (S-ERC) type is used when non-axial forces are generated on the shear bolts as the tanker moves in case of an emergency. These bolts are sheared which instantly closes the two valves present inside the ERC thus preventing any spillage.

While Cable release (C-ERC) type is used when non-axial forces are generated as the tanker moves in case of an emergency and these forces are transferred on the ERC spring plungers through a cable. With this the ERC gets separated with instant closing of the two valves inside the ERC causing minimum spillage.

Key features of C-ERC

- No extra spares required to reassemble once activated

- Breaking force can be adjusted with same arrangement