ACCESSORIES

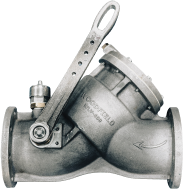

LOADING VALVE

WLV

Our products are specifically designed for top-loading refined fuels and other low-viscosity lube oils. They are operated manually in “dead man” style with spring-loaded handle without detente. An operator has to be present whenever the product is flowing into the tank.

- 2 stage "soft" close greatly reduces hydraulic hammer when valve is closed against a flowing product

- Available in 3", 4" and 6" sizes with TTMA inlet and outlet flanged connections

- Optional integral vacuum breaker

- Optional remote operation handle

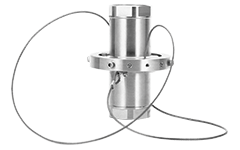

API COUPLER

WV400

The WV 400 API Coupler is developed based on our decades of experience and understanding of bottom-loading applications. This product is rugged and low-maintenance while delivering efficient performance for years.

- Snap on functionality with unique stainless steel 4 lug design

- Stainless Steel outer sleeve for long life durability

- Applications: Petroleum & Hydrocarbons

- Hard Anodized Aluminum body (A356-76)

Easy Strip Serviceability - Working Pressure: Up to 10 bar (145 psi)

- Max surge pressure: Up to 34 bar (493 psi)

- Operating temperature: -15°C to +90°C (-5°F to +194°F)

- Weight 18.7 # (8.5 kg)

- 4" TTMA Flange

QUICK DRY COUPLING

W-QDC

W-QDC is a two-stage coupling designed and manufactured to ensure safe spillage-free operation and provide positive sealing every time. This coupling is used with hoses and loading arms for transferring products from the terminal to the tanker or vice versa. It is capable of handling various chemical services.

- Chemical, Petrochemical, LPG/Propane/Butane services

- Safe & reliable

- Easy to use

- Can handle explosive & hazardous materials

- Safety factor 5

- Leak free operation

- Robust construction Easy to maintain

- ATEX compliant

- CE - Certified

EMERGENCY

RELEASE COUPLING

S-ERC

(SHEAR PIN TYPE)

Non-axial forces are generated on the shear bolts as the tanker moves in case of an emergency. Since these bolts are sheared, they instantly close the two valves present inside the ERC and prevent spillage.

C-ERC

(CABLE RELEASE TYPE)

Non-axial forces are generated when a tanker moves, in case of an emergency. These forces are transferred to the ERC spring plungers by a cable, which separates them and instantly shuts both valves inside. This helps achieve minimum spillage.

- No extra spares required to reassemble once activated

- Breaking force can be adjusted with same arrangement

- Safe & Reliable

- Spill-free Separation

- High flow rate / Low pressure drop

- Simple design & easy to maintain onsite

- Coupling automatically senses an excessive load and closes the valves and disconnects

CONTACT

Locations

-

13641 Dublin Court Stafford,

Texas 77477 -

+1 (803) 272-6313

-

sales.usa@woodfieldsystems.com

-

Avda. San Francisco Javier, 9 Off. 11-29,

41018 Seville, Spain -

+34 955 300 424

-

sales.es@woodfieldsystems.com

-

Nitco Biz Park, Plot C-19, Road 16, Wagle

Estate, Thane(W) - 400604, Maharashtra, India. -

+91 22 67040000

-

sales@woodfieldsystems.com

-

Marine House, Tyler Way, Swalecliffe Whitstable,

Kent, CT5 2RS United Kingdom -

+44 1227 793351

-

sales@woodfieldsystemsltd.com

-

Acueducto de Guadalupe CDMX. C.P. 07279.

Alcaldía. Gustavo A. Madero.Mexico -

+52 55 5064 6561

-

sales.mx@woodfieldsystems.com

ilemus@woodfieldsystems.com.mx

-

Woodfield Systems FZ-LLC

Level 9, The H Office Tower,

One Sheikh Zayed Road

Dubai, UAE -

+971 4 372 1354