LNG Truck Loading Package. Design, engineer, fabricate, assemble, test and supply LNG custody transfer skid system. Scope consisted of 3” Skid mounted Flow metering system with Coriolis Mass Flow Meter, Batch Controller, Cryogenic Flow Control Valves and Isolation Valves, Cryogenic Piping, Control panel, Vehicle Grounding System, Loading Arms, etc.

Ammonia Dosing Package. Design, engineer, fabricate, assemble, test and supply Ammonia Dosing skid system. Scope consisted of 2 x 100% metering pump system as per API 675 standard which consisted of 2 x 100% metering pumps, pulsation dampeners, isolation valves, storage tank and control panels, etc.

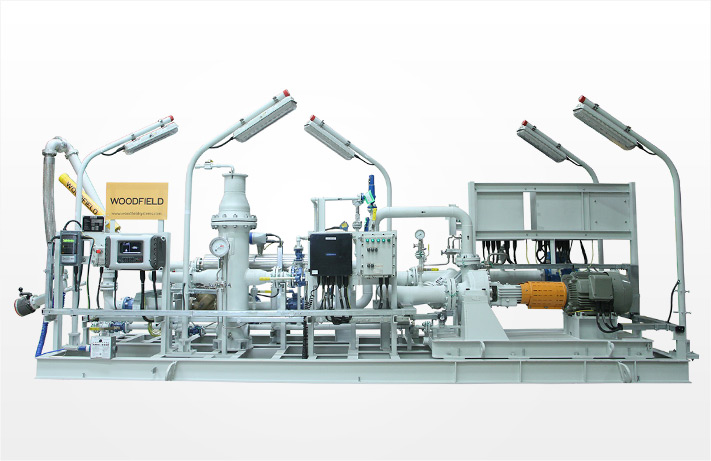

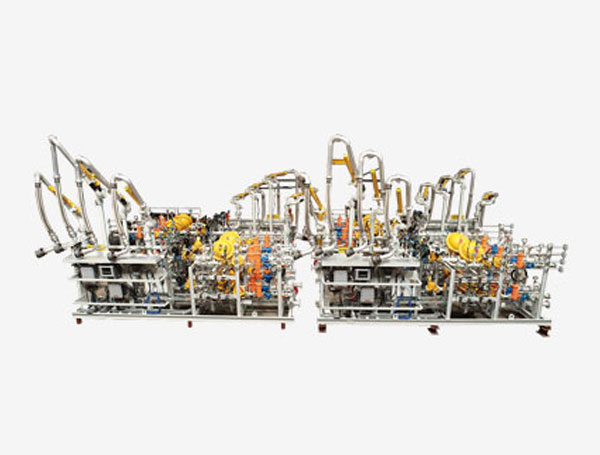

Pumping, metering & measuring system. Design, engineer, fabricate, assemble, test and supply Pump & custody transfer flow metering skid system for truck loading. Scope consisted of Loading pump system, flow metering system & loading arm each for Gasoline, Diesel & Kerosene. System includes Loading Pumps of Centrifugal type as per API610, strainer, custody transfer Coriolis Mass Flow Meter as per API MPMS 5.6, Digital flow control valves, prover connection arrangements Vehicle Grounding & Overfill protection system, control panels, batch controller & Loading Arms as per API RP1004 etc.

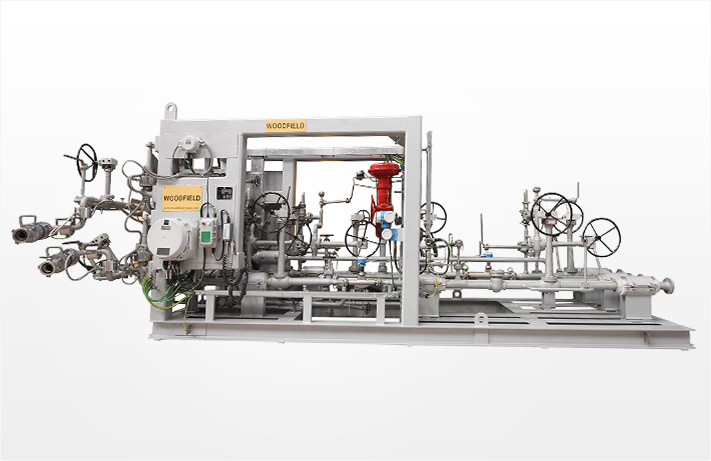

LPG loading system. Design, engineer, fabricate, assemble, test and supply loading skid system for LPG/Butane/Propane. Scope consisted of flow metering system and loading arms for LPG/Butane/Propane. System includes Strainer, Coriolis Mass Flow Meter, Flow Control Valves, shut-off valves, Vehicle Grounding System, Batch controller, control panels, Loading Arms, etc.

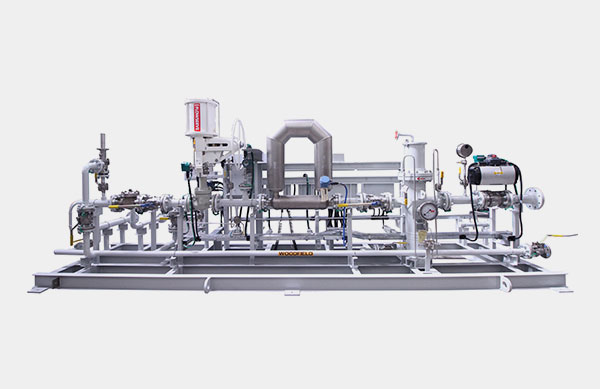

LPG Blending package. Design, engineer, fabricate, assemble, test and supply LPG Blending skid system with Propane & Butane.Scope consisted of automatic blending system for LPG with Propane & Butane. System includes individual flow metering & control system with Strainer, Coriolis Mass Flow Meter, Flow Control Valves each for Propane & Butane line followed by static mixer for homogeneous blending , pressure control valve & blending PLC with control panel.

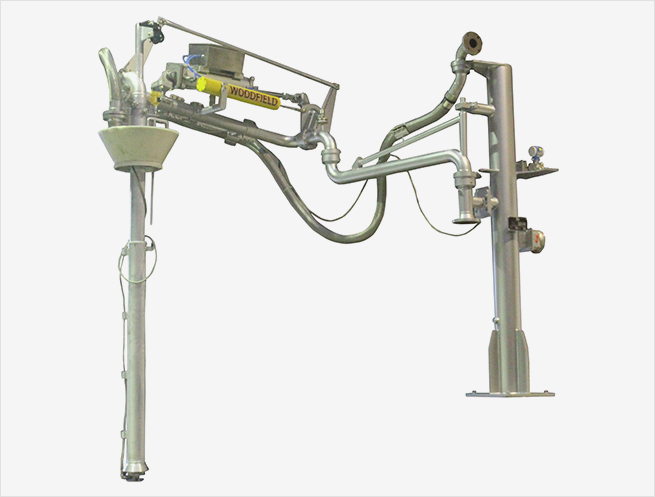

ETHANOL Loading & Blending SYSTEM. Design, engineer, fabricate, assemble, test and supply loading skid system for Ethanol with blend of Gasoline. Scope consisted of flow metering system and loading arms for Ethanol & blending system for Gasoline. System includes Strainer, Positive displacement flow meter, Digital flow control valve, Vehicle grounding & Overfill protection system, batch controllers, control panels, Loading Arms, etc.

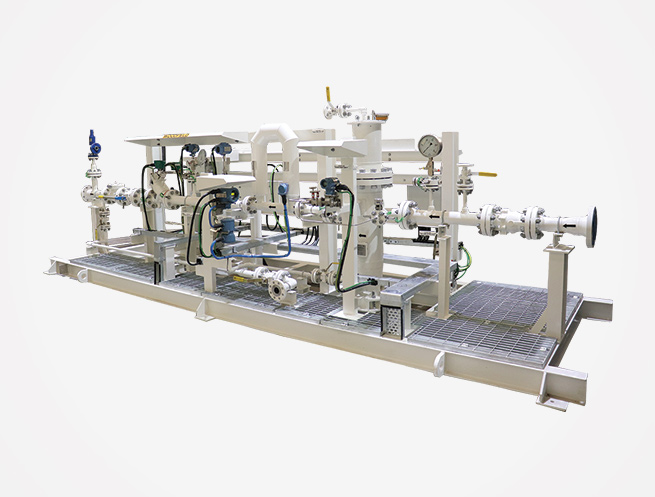

Complete custom engineered Metering Skid Systems for truck and rail loading/unloading hazardous liquid materials and gases. Explosion proof rating with ground monitoring and local batch controller interfaced to central automation system if required. Custody transfer metering with flow control, pressure & temperature sensing and remote/emergency stop facility.

Complete custom engineered Metering Skid Systems, featuring principal system components from the world’s leading manufacturers. Metering technology to suit the application, Coriolis, PD or Turbine. Digital Control Valves with flow, pressure and temperature sensing. Control and automation systems to ensure safe and accurate product transfer.

FS-6 Folding Stairs. For safe access to the top of tank trucks, rail cars or ISO containers. Available in aluminum, galvanized carbon steel or stainless steel. From 3 to 11 steps, tension spring or pneumatic operation. Available widths from 600mm to 1830mm. Equipped with serrated non slip steps, hand, knee and toe rails. Supported or self supported design. Tracking models also available.

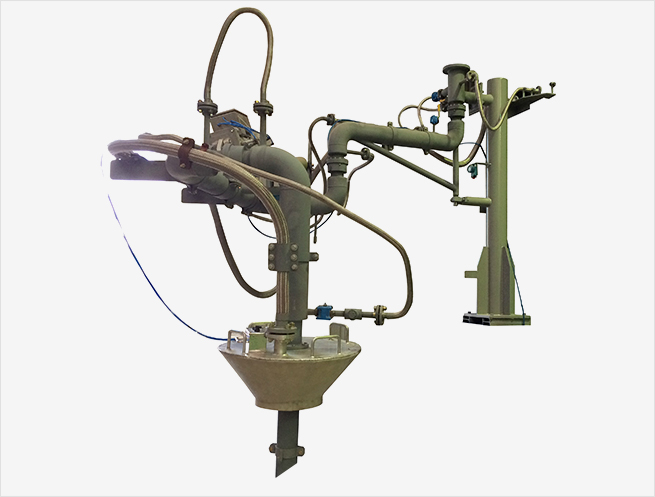

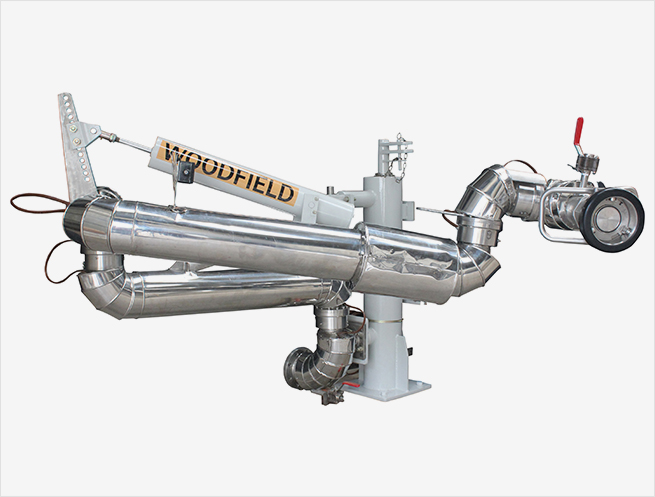

W443-JR Steam Jacketed Top Loading Arms for viscous products that require constant heating. Asphalt, bitumen, molten sulphur etc. In carbon steel or stainless steel with sizes of 3” x 4”, 4” x 6” and 6” x 8”. Typically with Vapour Recovery, Liquid Level Sensing, Pneumatic Operation. Arms are fully insulated. Other heat mediums of hot oil or electric trace heating available.

Custom Safe Access Equipment. Specifically engineered to suit each loading/unloading/inspection application. Above features pneumatically powered vertically operated Safety Cages with separate Folding Stairs for ISO Container Tank loading of hazardous chemicals. System includes Safety Interlocks and Emergency Exit Door within the Safety Cage.

WG-96 Gangway for safe access to the top of tank trucks, rail cars or ISO containers. Available in aluminum, galvanized carbon steel or stainless steel. Up to 144” long, tension spring or pneumatic operation. Available widths from 600mm to 1830mm. Equipped with serrated non slip walkway, hand, knee and toe rails. Supported or self supported design. Tracking models also available.

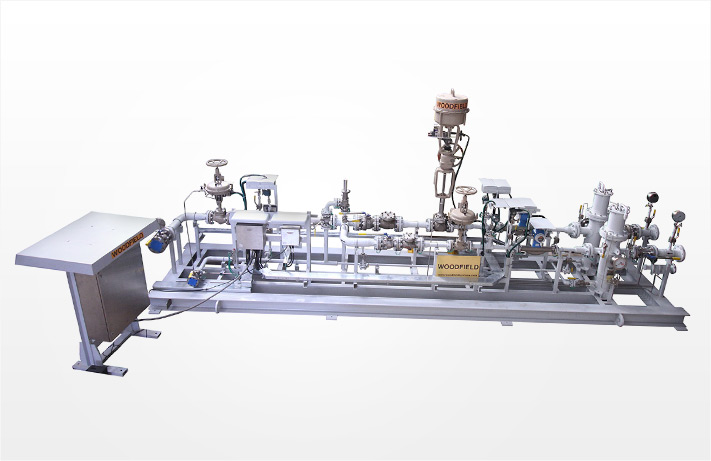

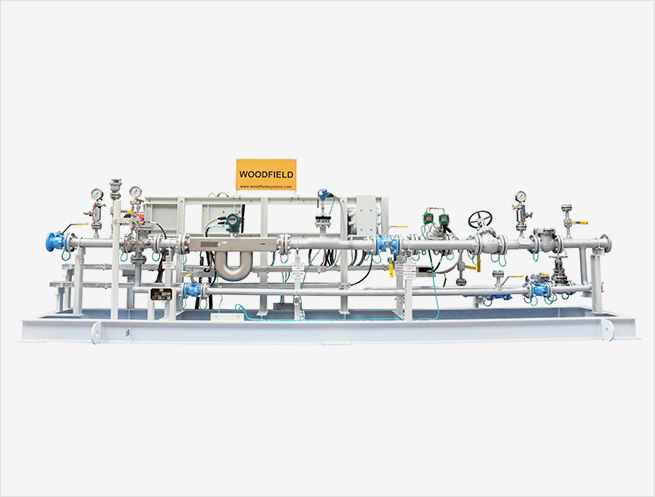

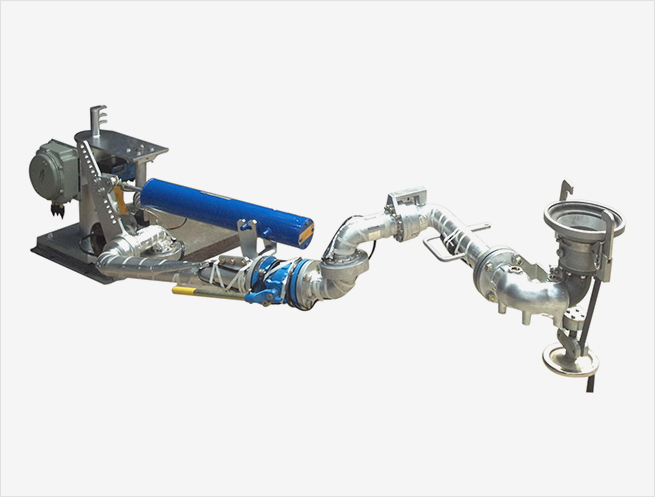

Truck Unloading Skid with unloading arms for Lube Oil.

Custom engineered unloading and metering skid system, including redundant pumping system, featuring principal system components from the world’s leading manufacturers. Metering technology – Coriolis Meter to suit application. Digital Control Valves with pressure and temperature sensing. Control and automation sensors to ensure safe and accurate product transfer.

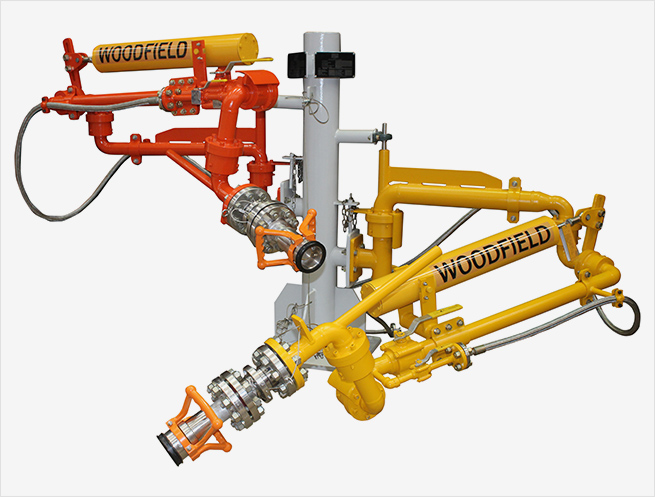

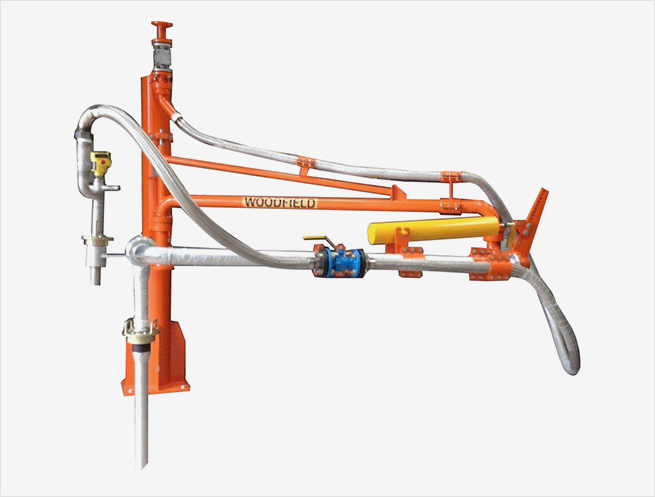

Truck loading Skid with loading arms for LPG

Custom engineered loading and metering skid system, featuring principal system components from the world’s leading manufacturers. Metering technology – Coriolis Meter to suit application. Digital Control Valves with pressure and temperature sensing. Grounding, Control & automation sensors to ensure safe and accurate product transfer.

Gasoline and Diesel service Custody transfer truck loading skid system with Ethanol and Bio-diesel blending and Endura Diesel and Exelon Nitro 95 additive lines designed, engineered, fabricated, assembled, tested and supplied by Woodfield. Scope consisted of 4x 4” loading lines, 4x 2” blending, 7x 1/2” additive lines comprised Skid with Custody certified PD Meters, Batch Controllers, Additive Injection Blocks, Digital Control Valves, Pneumatic Actuated On-Off Valves, Isolation Valves, Check valves, Rack Monitor with Overfill Protection, Power Isolation Switch, Junction Boxes, Emergency Hand Switch, Bottom Loading Arms and Vapour Return Hose with Parking Position Sensors etc.